Airfoil (MH-104)#

Problem description#

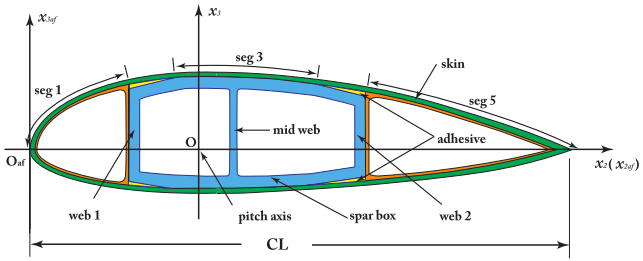

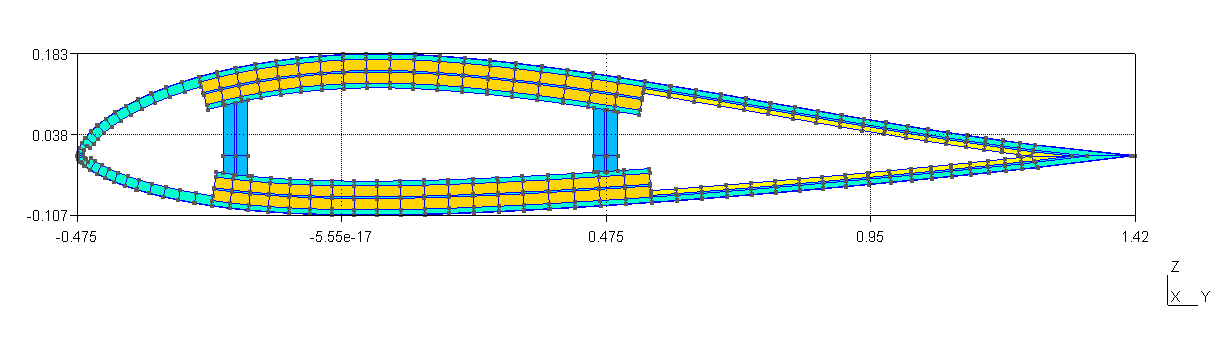

Figure 50 Sketch of a cross section for a typical wind turbine blade [CHEN2010].#

This example demonstrates the capability of building a cross section having an airfoil shape, which is commonly seen on wind turbine blades or helicopter rotor blades.

This example is also studied in [CHEN2010].

A sketch of a cross section for a typical wind turbine blade is shown in Fig. 50.

The airfoil is MH 104 (http://m-selig.ae.illinois.edu/ads/coord_database.html#M).

In this example, the chord length \(CL=1.9\) m.

The origin O is set to the point at 1/4 of the chord.

Twist angle \(\theta\) is \(0^\circ\).

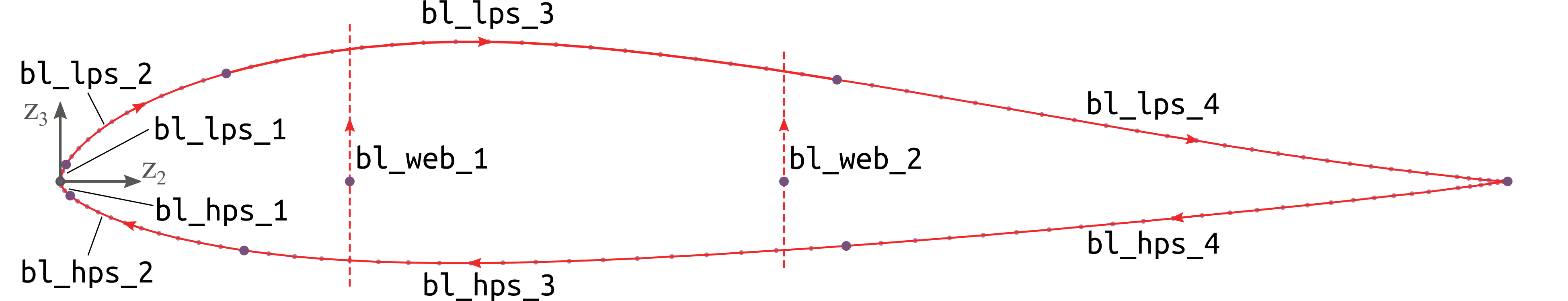

There are two webs, whose right boundaries are at the 20% and 50% location of the chord, respectively.

Both low pressure and high pressure surfaces have four segments.

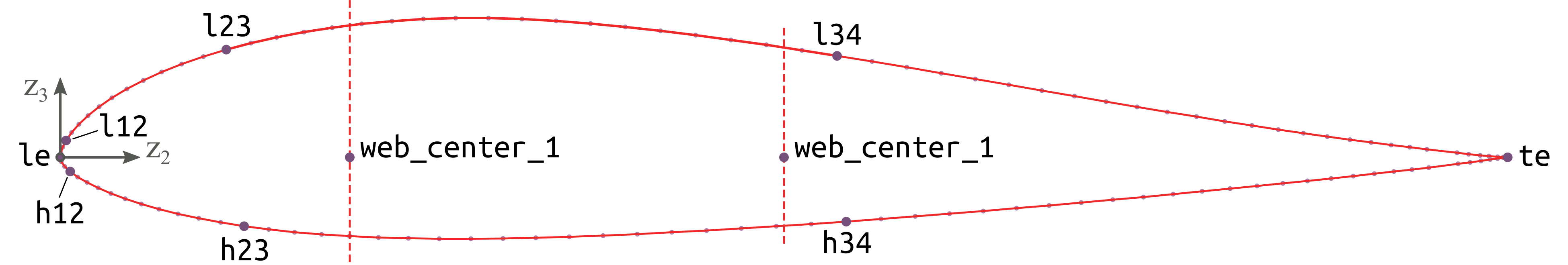

The dividing points between segments are listed in Table 27.

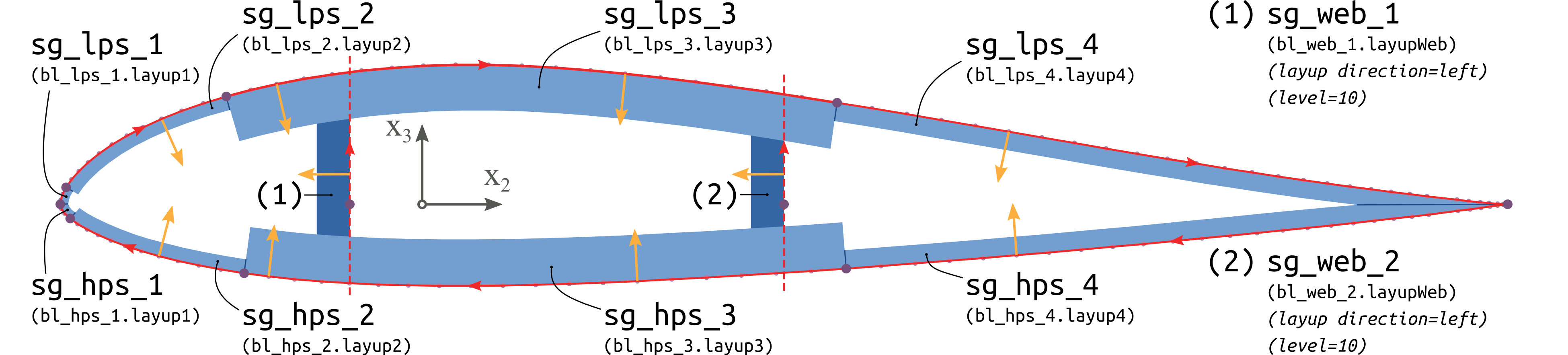

Materials are given in Table 28 and layups are given in Table 29.

A complete \(6\times 6\) stiffness matrix is given in Table 30.

Complete input files can be found in examples\ex_airfoil\, including mh104.xml, basepoints.dat, baselines.xml, materials.xml, and layups.xml.

Between segments |

Low pressure surface |

High pressure surface |

|---|---|---|

\((x, y)\) |

\((x, y)\) |

|

1 and 2 |

(0.004053940, 0.011734800) |

(0.006824530, -0.009881650) |

2 and 3 |

(0.114739930, 0.074571970) |

(0.126956710, -0.047620490) |

3 and 4 |

(0.536615950, 0.070226120) |

(0.542952100, -0.044437080) |

Figure 51 Base points of the tube cross section.#

Figure 52 Base lines of the tube cross section.#

Figure 53 Segments of the tube cross section.#

Figure 54 Meshed cross section viewed in Gmsh.#

Name |

Type |

Density |

\(E_{1}\) |

\(E_{2}\) |

\(E_{3}\) |

\(G_{12}\) |

\(G_{13}\) |

\(G_{23}\) |

\(\nu_{12}\) |

\(\nu_{13}\) |

\(\nu_{23}\) |

|---|---|---|---|---|---|---|---|---|---|---|---|

\(10^3\ \mathrm{kg/m^3}\) |

\(\mathrm{GPa}\) |

\(\mathrm{GPa}\) |

\(\mathrm{GPa}\) |

\(\mathrm{GPa}\) |

\(\mathrm{GPa}\) |

\(\mathrm{GPa}\) |

|||||

Uni-directional FRP |

orthotropic |

1.86 |

37.00 |

9.00 |

9.00 |

4.00 |

4.00 |

4.00 |

0.28 |

0.28 |

0.28 |

Double-bias FRP |

orthotropic |

1.83 |

10.30 |

10.30 |

10.30 |

8.00 |

8.00 |

8.00 |

0.30 |

0.30 |

0.30 |

Gelcoat |

orthotropic |

1.83 |

1e-8 |

1e-8 |

1e-8 |

1e-9 |

1e-9 |

1e-9 |

0.30 |

0.30 |

0.30 |

Nexus |

orthotropic |

1.664 |

10.30 |

10.30 |

10.30 |

8.00 |

8.00 |

8.00 |

0.30 |

0.30 |

0.30 |

Balsa |

orthotropic |

0.128 |

0.01 |

0.01 |

0.01 |

2e-4 |

2e-4 |

2e-4 |

0.30 |

0.30 |

0.30 |

Name |

Layer |

Material |

Ply thickness |

Orientation |

Number of plies |

|---|---|---|---|---|---|

\(\mathrm{m}\) |

\(\circ\) |

||||

layup_1 |

1 |

Gelcoat |

0.000381 |

0 |

1 |

2 |

Nexus |

0.00051 |

0 |

1 |

|

3 |

Double-bias FRP |

0.00053 |

20 |

18 |

|

layup_2 |

1 |

Gelcoat |

0.000381 |

0 |

1 |

2 |

Nexus |

0.00051 |

0 |

1 |

|

3 |

Double-bias FRP |

0.00053 |

20 |

33 |

|

layup_3 |

1 |

Gelcoat |

0.000381 |

0 |

1 |

2 |

Nexus |

0.00051 |

0 |

1 |

|

3 |

Double-bias FRP |

0.00053 |

20 |

17 |

|

4 |

Uni-directional FRP |

0.00053 |

30 |

38 |

|

5 |

Balsa |

0.003125 |

0 |

1 |

|

6 |

Uni-directional FRP |

0.00053 |

30 |

37 |

|

7 |

Double-bias FRP |

0.00053 |

20 |

16 |

|

layup_4 |

1 |

Gelcoat |

0.000381 |

0 |

1 |

2 |

Nexus |

0.00051 |

0 |

1 |

|

3 |

Double-bias FRP |

0.00053 |

20 |

17 |

|

4 |

Balsa |

0.003125 |

0 |

1 |

|

5 |

Double-bias FRP |

0.00053 |

0 |

16 |

|

layup_web |

1 |

Uni-directional FRP |

0.00053 |

0 |

38 |

2 |

Balsa |

0.003125 |

0 |

1 |

|

3 |

Uni-directional FRP |

0.00053 |

0 |

38 |

Result#

\(\phantom{-}2.395\times 10^9\) |

\(\phantom{-}1.588\times 10^6\) |

\(\phantom{-}7.215\times 10^6\) |

\(-3.358\times 10^7\) |

\(\phantom{-}6.993\times 10^7\) |

\(-5.556\times 10^8\) |

\(\phantom{-}1.588\times 10^6\) |

\(\phantom{-}4.307\times 10^8\) |

\(-3.609\times 10^6\) |

\(-1.777\times 10^7\) |

\(\phantom{-}1.507\times 10^7\) |

\(\phantom{-}2.652\times 10^5\) |

\(\phantom{-}7.215\times 10^6\) |

\(-3.609\times 10^6\) |

\(\phantom{-}2.828\times 10^7\) |

\(\phantom{-}8.440\times 10^5\) |

\(\phantom{-}2.983\times 10^5\) |

\(-5.260\times 10^6\) |

\(-3.358\times 10^7\) |

\(-1.777\times 10^7\) |

\(\phantom{-}8.440\times 10^5\) |

\(\phantom{-}2.236\times 10^7\) |

\(-2.024\times 10^6\) |

\(\phantom{-}2.202\times 10^6\) |

\(\phantom{-}6.993\times 10^7\) |

\(\phantom{-}1.507\times 10^7\) |

\(\phantom{-}2.983\times 10^5\) |

\(-2.024\times 10^6\) |

\(\phantom{-}2.144\times 10^7\) |

\(-9.137\times 10^6\) |

\(-5.556\times 10^8\) |

\(\phantom{-}2.652\times 10^5\) |

\(-5.260\times 10^6\) |

\(\phantom{-}2.202\times 10^6\) |

\(-9.137\times 10^6\) |

\(\phantom{-}4.823\times 10^8\) |

\(\phantom{-}2.389\times 10^9\) |

\(\phantom{-}1.524\times 10^6\) |

\(\phantom{-}6.734\times 10^6\) |

\(-3.382\times 10^7\) |

\(-2.627\times 10^7\) |

\(-4.736\times 10^8\) |

\(\phantom{-}1.524\times 10^6\) |

\(\phantom{-}4.334\times 10^8\) |

\(-3.741\times 10^6\) |

\(-2.935\times 10^5\) |

\(\phantom{-}1.527\times 10^7\) |

\(\phantom{-}3.835\times 10^5\) |

\(\phantom{-}6.734\times 10^6\) |

\(-3.741\times 10^6\) |

\(\phantom{-}2.743\times 10^7\) |

\(-4.592\times 10^4\) |

\(-6.869\times 10^2\) |

\(-4.742\times 10^6\) |

\(-3.382\times 10^7\) |

\(-2.935\times 10^5\) |

\(-4.592\times 10^4\) |

\(\phantom{-}2.167\times 10^7\) |

\(-6.279\times 10^4\) |

\(\phantom{-}1.430\times 10^6\) |

\(-2.627\times 10^7\) |

\(\phantom{-}1.527\times 10^7\) |

\(-6.869\times 10^2\) |

\(-6.279\times 10^4\) |

\(\phantom{-}1.970\times 10^7\) |

\(\phantom{-}1.209\times 10^7\) |

\(-4.736\times 10^8\) |

\(\phantom{-}3.835\times 10^5\) |

\(-4.742\times 10^6\) |

\(\phantom{-}1.430\times 10^6\) |

\(\phantom{-}1.209\times 10^7\) |

\(\phantom{-}4.406\times 10^8\) |

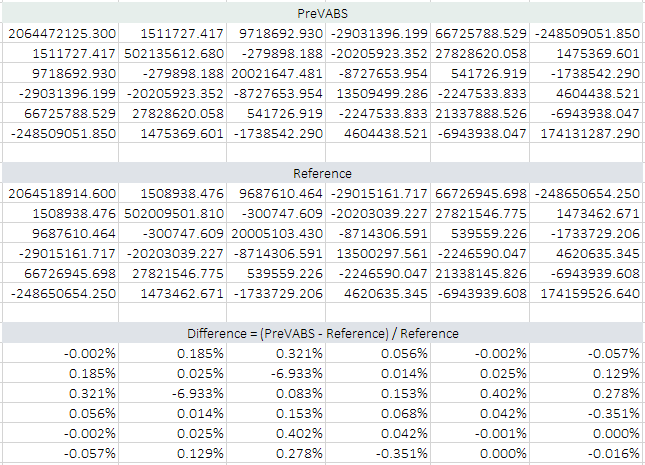

Note

The errors between the result and the reference are caused by the difference of modeling of the trailing edge. If reduce the trailing edge skin to a single thin layer, then the difference between the trailing edge shapes is minimized, and the two resulting stiffness matrices are basically the same, as shown in Fig. 55.

Figure 55 Comparison of stiffness matrices after modifying the trailing edge.#