2.2. Add Layup#

Users can use function New layups  to create Solid-Composite sections which will be used later.

There are two ways to do this: Fast generation and Read from file.

to create Solid-Composite sections which will be used later.

There are two ways to do this: Fast generation and Read from file.

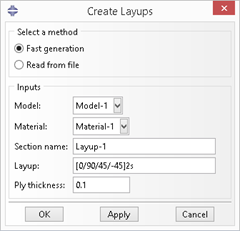

2.2.1. Fast generation#

In this method, user can generate a layup through a rule, such as [0/90/45/-45]2s. User needs to first create a material. Then provide a new composite section name and the layup rule. The thickness at the last is for each ply. This method is only suitable for layups with a single material having different fiber orientations and all plies with the same thickness, which is the most common case in industry

Figure 2.2.1.1 Fast generation of layup.#

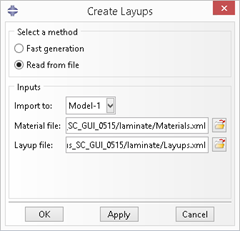

2.2.2. Read from file#

In this method, user needs to prepare a material file and a layup file. To create composite sections, select Read from file in the dialog box, and choose the material file and the layup file, then click OK. Both the material file and layup file should use the XML format and details are described below. Users are encouraged to have some basic knowledge on XML files. A quick and simple tutorial can be found at http://www.tutorialspoint.com/xml/index.htm.

Figure 2.2.2.1 Read from file.#

Material file#

The root element is <materials></materials> and each <material></material> sub-element store one material.

For the current version, we can only deal with materials with density and elastic properties.

<materials>

<material type="ENGINEERING CONSTANTS">

<name>iso5_1</name>

<density>1.860000E+03</density>

<e1>3.7000E+10</e1>

<e2>9.0000E+09</e2>

<e3>9.0000E+09</e3>

<g12>4.0000E+09</g12>

<g13>4.0000E+09</g13>

<g23>4.0000E+09</g23>

<nu12>0.28</nu12>

<nu13>0.28</nu13>

<nu23>0.28</nu23>

</material>

<material>

...

</material>

...

</materials>

Each material has a type attribute, which has the same definition as Abaqus, ISOTROPIC, ENGINEERING CONSTANTS, ORTHOTROPIC or ANISOTROPIC. For each material, user needs to provide a unique name. The density is optional. When omitted, the default value 1.0 will be used. The constants of elastic properties for each type are the same as those in Abaqus.

For ISOTROPIC, 2 constants are needed: ‘e’ and ‘nu’.

For ENGINEERING CONSTANTS, 9 constants are needed: ‘e1’, ‘e2’, ‘e3’, ‘g12’, ‘g13’, ‘g23’, ‘nu12’, ‘nu13’, and ‘nu23’.

For ORTHOTROPIC, 9 constants are needed: ‘d1111’, ‘d1122’, ‘d2222’, ‘d1133’, ‘d2233’, ‘d3333’, ‘d1212’, ‘d1313’, and ‘d2323’.

For ANISOTROPIC, 21 constants are needed: ‘d1111’, ‘d1122’, ‘d2222’, ‘d1133’, ‘d2233’, ‘d3333’, ‘d1112’, ‘d2212’, ‘d3312’, ‘d1212’, ‘d1113’, ‘d2213’, ‘d3313’, ‘d1213’, ‘d1313’, ‘d1123’, ‘d2223’, ‘d3323’, ‘d1223’, ‘d1323’, and ‘d2323’.

Layup file#

The root element is <layups></layups> and each <layup></layup> sub-element stores one layup.

<layups>

<layup>

<name>layup_1</name>

<layer>

<thickness>0.1</thickness>

<material>mat_1</material>

<fiber_orient>0</fiber_orient>

</layer>

<layer>

...

</layer>

...

</layup>

...

</layups>

For each layup, user needs to provide a unique ‘name’. Each layup has any number of layers, and for each layer, user needs to provide thickness, material name and fiber orientation.